PRODUCT INFORMATION

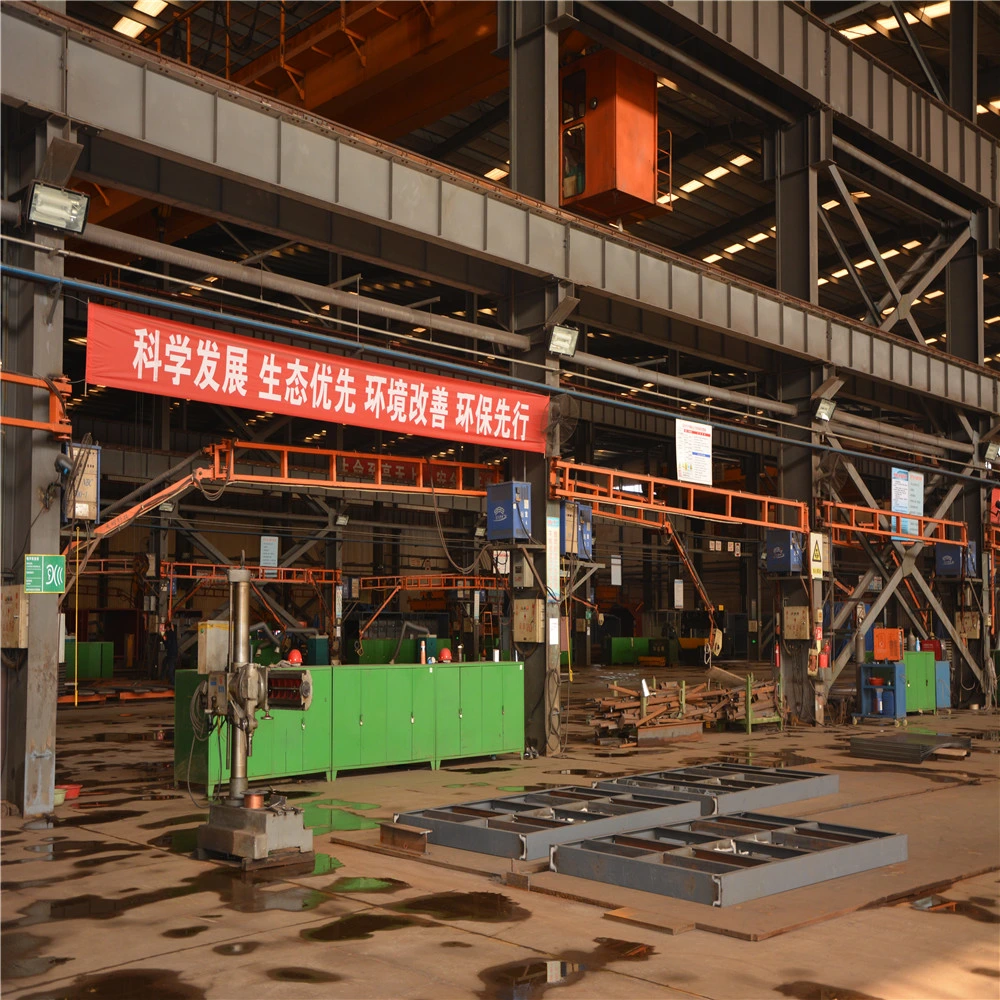

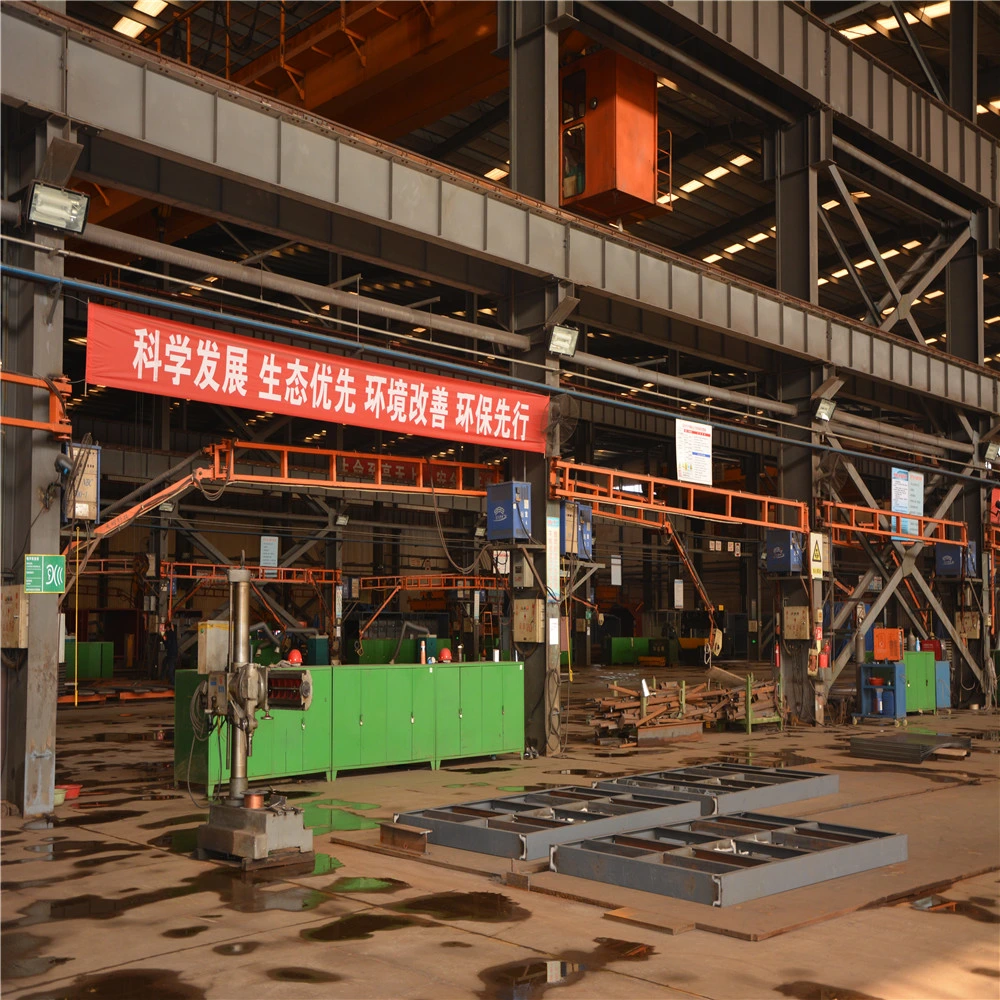

Cutting and Welding Workshop

The cutting and welding workshop is built for storage of raw materials, cutting of sheet materials and section bars as well as welding of spare parts and tower crane components, which include mast sections, jib, turntable, pull rod, trolley cabin, trolleying cabin, hook, ash bucket. There are over 80 sets of welding and other processing equipment in the workshop. Specifically, we have 2 numerical control plasma cutting streamlines, welding robots for slewing parts, welding robots for mast sections and main limb, and over 40 sets of small or large tooling equipment for production of every component. Hence, from cutting to tailor-welding, processing of semi-finished components, assembly welding and assembling of spare parts can be all conducted in this workshop. Further, high production efficiency can be ensured.

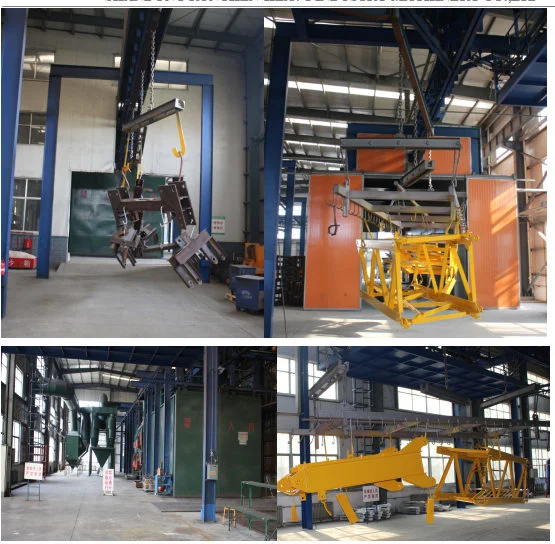

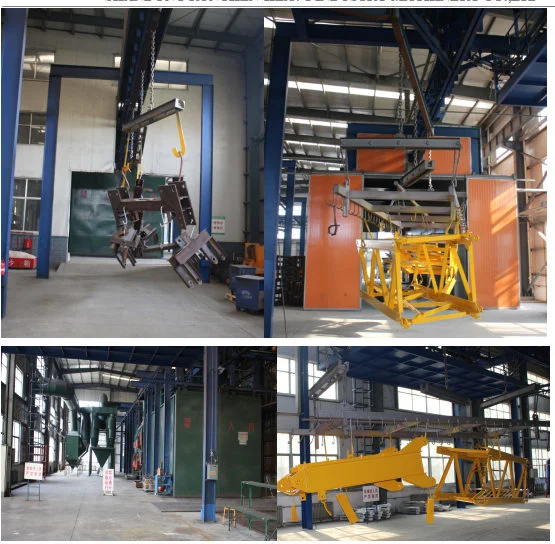

Blasting and Painting Workshop

The blasting and painting workshop is a transfer station of semi-finished tower crane components. It is equipped with a fully automatic blasting and painting assembly line and more than 20 sets of various lifting machines and jigs. These semi-finished components go through processing of blasting, rust cleaning and surface painting in this workshop.

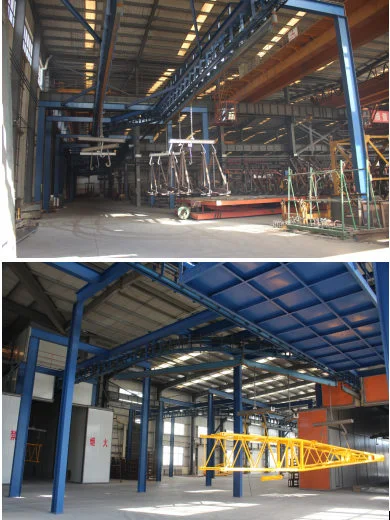

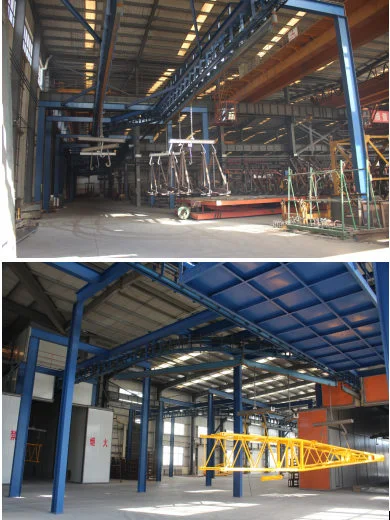

Finished Products Workshop

With over 20 sets of various lifting equipment, finished products workshop is used for storage of finished tower crane components and packaging and shipping of tower cranes. These finished components are organized in order for easy packaging and shipping afterwards, thus significantly improving delivery efficiency.

Shandong Runchen Heavy Industry Machinery Co., Ltd as a large tower cranes manufacturer, it integrates development, design and production together. It is also one of the largest construction bases of tower cranes in China.

| Type | RCD6050-20T |

| Free standing | 42.79m |

| Jib Length | 60m |

| Max Load | 20 Ton |

| Tip load | 5.0Ton |

| Mast section size | 2*2*3.0m |

| Mast section material | Q345B angle steel |

| Item | Mechanism | Speed (m/min) | Rope capacity | Motor(KW) | |

| Hoist Mechanism | 150LCC50 | 2 times rate | 0-82.8 | 770m | 110 |

| 4 times rate | 0-41.4 | ||||

| Luffing Mechanism | 85BWZA55 | 3.5 | 63 | ||

| Slewing Mechanism | RCV185 | 0-0.7m/min | 3*185NM | ||

| Travelling Mechanism | RT643 | 0-16-32m/min | 6*2.6 | ||

| Main Supply | 380V/50HZ | ||||

Cutting and Welding Workshop

The cutting and welding workshop is built for storage of raw materials, cutting of sheet materials and section bars as well as welding of spare parts and tower crane components, which include mast sections, jib, turntable, pull rod, trolley cabin, trolleying cabin, hook, ash bucket. There are over 80 sets of welding and other processing equipment in the workshop. Specifically, we have 2 numerical control plasma cutting streamlines, welding robots for slewing parts, welding robots for mast sections and main limb, and over 40 sets of small or large tooling equipment for production of every component. Hence, from cutting to tailor-welding, processing of semi-finished components, assembly welding and assembling of spare parts can be all conducted in this workshop. Further, high production efficiency can be ensured.

Blasting and Painting Workshop

The blasting and painting workshop is a transfer station of semi-finished tower crane components. It is equipped with a fully automatic blasting and painting assembly line and more than 20 sets of various lifting machines and jigs. These semi-finished components go through processing of blasting, rust cleaning and surface painting in this workshop.

Finished Products Workshop

With over 20 sets of various lifting equipment, finished products workshop is used for storage of finished tower crane components and packaging and shipping of tower cranes. These finished components are organized in order for easy packaging and shipping afterwards, thus significantly improving delivery efficiency.

Shandong Runchen Heavy Industry Machinery Co., Ltd as a large tower cranes manufacturer, it integrates development, design and production together. It is also one of the largest construction bases of tower cranes in China.